| Introduction : |

Testing of the new PC AT at I.B.M.'s Larkspur factory ( Gourock - Renfrewshire ) was automated by I.M.M.'s own software engineers, although there were a few things that couldn't be done by software alone. Apart from the electronic aspects of testing, I.B.M. engineers needed to check the illumination of LED's and swap floppy disks during the test sequence. |

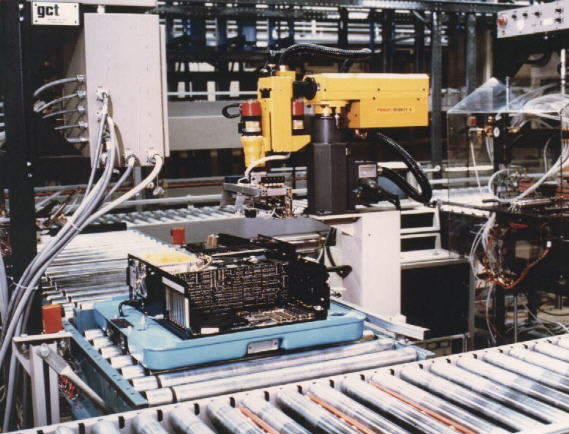

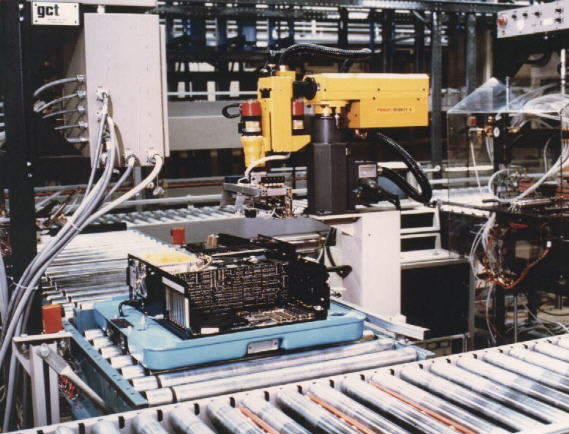

| Fanuc Robot A3-0 waits to test an I.B.M PC AT : |

|

| Solution : |

Using a touch probe, the Fanuc Robot A3-0 accurately locates the front of the PC and the disk drive slot. Immediately it places the photo sensors on the gripper over the power and hard disk LED's allowing the test station to check their correct operation. Upon receiving instructions from the test computer, the robot collects a pre-programmed 5 1/4" floppy disk from the rack and, using its measured data, positions itself and exchanges the travel card in the disk drive for the 'test' disk. Later during the test sequence, the robot removes the 'test' disk and replaces it with a 'run-in' disk previously collected from the disk dispenser. During the disk exchanging process, the robot monitors the operation of the disk drive latch lever, the locking in of and spring eject of the disk within disk drive. The robot informs the test computer of the nature of the failure, providing data for quality analysis and re-working details. The computer leaves the test station and normally passes to the automated burn-in racks - failed computers return to the re-work area for remedial work to be carried out. |