| Introduction : |

The New Dertroit Hyatt Forge in Michigan USA produce half-shafts for Buick cars. To keep up with increasing car sales, they needed to produce one completed forged half-shaft every 6 seconds. To ensure this throughput, an upsetting press runs continuously striking one half-shaft every 6 seconds. Heating up such a huge quantity of steel bars ( 600 per hour ) needed a very high power induction heating system - 4 Mega-Watts to be precise. |

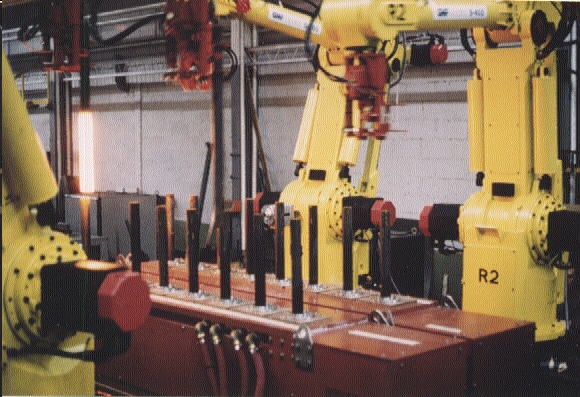

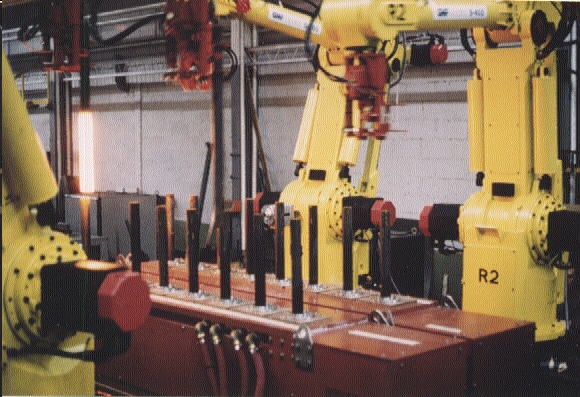

| 4 GMFanuc S400 Robots supply hot bars to upsetting press : |

|

| Solution : |

Radyne Limited of Wokingham were selected as the only company capable of producing such a powerfull system. Because of the link between Fanuc and GM in the USA, GMFanuc S400 robots were selected to transfer bars through the system. With a cycle time of 6 seconds to be met, 4 robots were required ( 2 robots loading the heater with cold bars and 2 robots unloading the hot bars from the heater and transferring them to the upsetting press. With the 4 robots working so closely together, anti-collission software is of primary importance. Should there any sort of a hiccup, the robots are programmed to unload the bars from the heater. After 90 seconds heating, the bars are extremely hot - approaching melting point, and any more heating time would cause the bars to melt, damaging the heater coils. |