| INTRODUCTION : |

With the current huge growth in the mobile telephone market, and the associated health scares regarding micro-wave emissions, the requirements for High Frequency Screening products has increased dramatically. With the very tight cost controls imposed during the manufacture of mobile telephones, producers of component parts must turn to the most cost effective automation equipment to retain their profit margins. |

| Spot welding and cutting machine : |

|

| REQUIREMENT : |

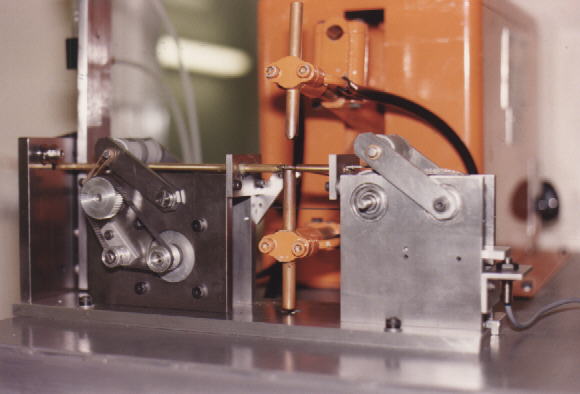

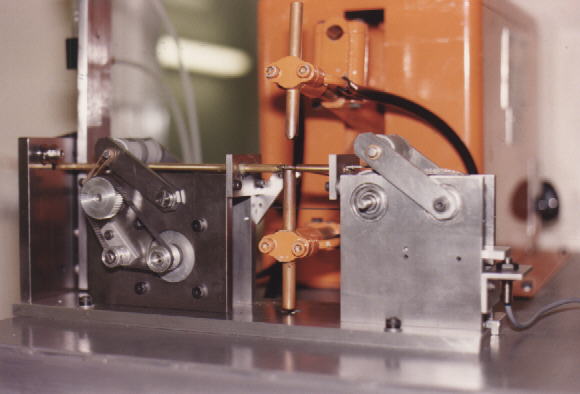

Illustrated above, is a very simple and cost effective solution to one such problem. The manufacturer was required to produce huge quantities of braid pieces, in several lengths, which must not ' un-knit ' during handling or installation. To accomplish this, the manufacturer spot welded the braid at the required position, and cut the braid in pieces - through the middle of the spot weld. |

| METHOD : |

The knitted screening braid ( which resembles the French Knitting we all did as children, with a cotton reel and 4 nails ), rises from a storage bin below the table ( on the right ), round a roller and across between the spot welder electrodes ( in the centre of the picture. Having been spot welded, the braid passes over the stepping motor drive unit, and then between the pneumatically operated cutter blades. Tangles are detected when the braid passes through a tilting plate - seen on the extreme right hand side of the picture. |

| Manual mode : | Auto mode : | Parameter mode : |

|

|

|

|

| CONTROL SYSTEM : |

In order to engineer the project in the most cost effective manner, the complete machine is controlled by an Amstrad 1512 Personal Computer. Software for the control system is written in Turbo Pascal. The menu driven operating system ( shown above ), allows the operator / setter to adjust and control the complete machine. |