| Introduction : |

The electronics industry's continual quest for ever higher speeds, has lead to an expansion in the ferrite core market. Traditional manual handling techniques can no longer cope with the increased through-put requirements - therefore robot technology takes the strain. Ferrite cores are manufactured from a specialist ' black powder ', dispensed in metered shots into a press mould tool. After the press has compacted the powder, the cores are fed out along a miniature belt conveyor. At this time, before baking, the core is just compressed powder, and rough handling will break the core. |

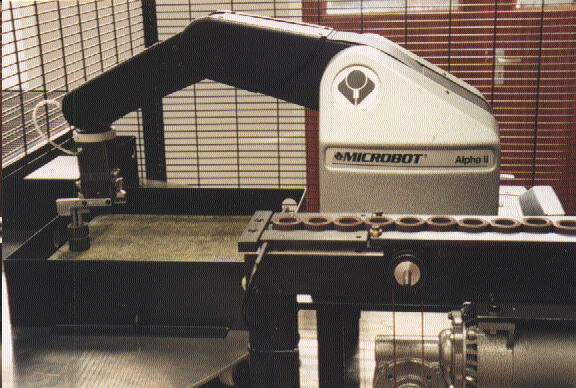

| Microbot Alpha II picks up cores from the infeed conveyor : |

|

| Solution : |

The Microbot Alpha II ( shown above ) delicately picks up individual cores from the conveyor and stacks them in pairs on a ceramic tile ( shown below ) - ready for loading into the oven for baking. The spacing between cores is critical, as restriction in the free circulation of heat causes inadequate curing - the robot spaces cores perfectly - every time. |

| The Alpha II robot palletises the cores ready for baking : |

|

| System Details : |

The Microbot Alpha II is a 5 axis robot, driven by stepping motors. The robot is supplied with a simple teach pendant, through which the users program may be entered. The program is stored in the robot controller memory. The robot controller is fitted with a number of digital inputs and outputs to interface it with the real world. In this application, the robot controls the infeed conveyor and the indexing table on which the ceramic tiles are placed. |