| INTRODUCTION : |

Crosslee PLC, from Hipperholm ( near Halifax - in West Yorkshire ), manufacture a large range of tumble dryers for growing markets in the U.K. and internationally. During the peak season, tumble dryers must be manufactured on a 24 hour per day, 7 days per week basis, totalling in excess of 3000 dryers per day. Hand loading of casing panels, apart from being an extremely boring repetitive job, involves the press operators handling razor sharp materials in an extremely noisy environment. Press operators are also exposed to a high risk of repetative strain injury caused by continually reaching into the press whilst carrying the sheet steel panels. Operator stress, together with failing existing press loading automation working in another cell led engineers to seek a new solution to falling production rates. Robotix, having carried out other work at Crosslee, were asked to look for a reliable method of press loading, capable of producing one panel every 12 seconds - day and night. |

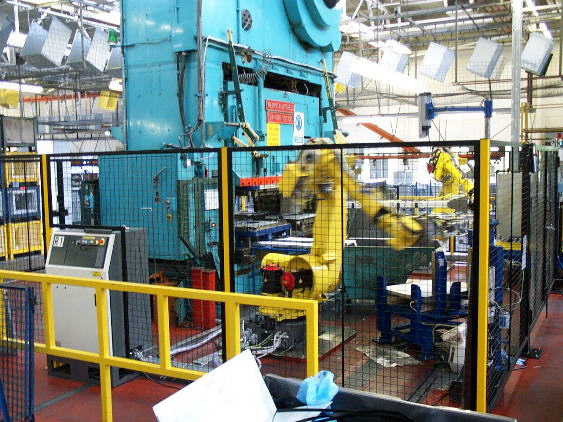

| 2 Fanuc R2000i robots work at the front of the press : |

|

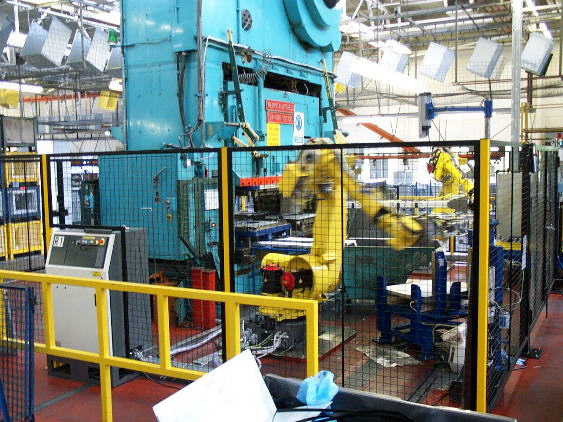

| and another Fanuc R2000i robot works at the back : |

|

| SOLUTION : |

Robotix installed three Fanuc R2000i robots working around this 400 ton Wilkins and Mitchell press. Panels require 4 press operations from blank to finished part. Robot 1 ( nearest to us in the top picture ) picks blank sheets from a stack of 500 placed on the infeed table. Exact positioning of the sheet is not critical, as the robot is equipped with a DVT camera system, identifying the exact pick-up position. Robot 1 - equipped with a double vacuum gripper, picks the part finished panel nearest to it, and moving through the press, puts down both panels - moving them one stage further on ( the panels are oiled by the robot during loading ). Robot 2 ( on the back of the press ) moves panels from operation 2 to operation 3 - at the same time, disposing of a picture frame shaped piece of scrap in the scrap bin. Robot 3 - also equipped with a double vacuum gripper, picks up the finished panel together with the operation 3 panel, and moving out of the press, puts down the part finished panel in the finishing tool. Robot 3 stacks the finished panels on the outfeed conveyor. Does the system meet the required throughput of 300 panels per hour ? Yes - it is currently producing 320 panels per hour. |

| Blanks go in on the left, finished panels out on the right : |

|

| OPERATOR FRIENDLY : |

Although robots are thought of as complicated ( especially when something goes wrong ), the 400 ton press loading system uses a text based operator interface to aid simplicity. Messages report anything requiring the operators attention whilst menus lead the operator through starting, stopping and manually operating the system. |